Product Search

Quickly find the products you need

Modular nitrogen generator

Nitrogen flow rate: 0.5~160Nm ²/h

Working temperature: 5-40 ° C

Minimum intake pressure: 0.6MPa

Nitrogen purity: 98~99.999%

Noise level:<70dB

Dew point temperature: -40 ° C~-70 ° C

Power specification: 220V 50Hz/AC110V DC24V

Nitrogen outlet pressure: 0.1-0.6MPa (adjustable and can be equipped with a built-in nitrogen tank)

Maximum ambient temperature:<45 ° C

Control mode: PLC programmable control, fully functional human-machine interface microcomputer controller

Category:

Keywords:

Product Description

Modular nitrogen generator features:

- High efficiency, low air-to-nitrogen ratio, thereby achieving energy saving and emission reduction, and improving economic benefits. The modular nitrogen generator uses high-performance molecular sieves, with a 99.99% air-to-nitrogen ratio reaching 4.2:1, while the traditional dual-tower nitrogen generator has a 99.99% air-to-nitrogen ratio of 5.5:1. For example, a 40Nm²/h modular nitrogen generator requires 2.8Nm²/min of compressed air, while a 40Nm²/h dual-tower nitrogen generator requires 3.7Nm²/min of compressed air, saving 24% of energy consumption.

- It adopts PLC programmable control program, equipped with high-resolution human-machine interaction, detects various data (air pressure, nitrogen pressure, nitrogen purity, nitrogen flow), and records operating conditions, etc. It realizes the automatic emptying of unqualified nitrogen and the energy-saving automatic pause function, maximizing energy savings.

- It adopts a unique control method combining solenoid valves and pneumatic valves, avoiding the traditional cumbersome multi-valve control structure, and the operation is stable and reliable.

- It adopts a high-strength aluminum alloy structure, which is non-corrosive and rust-free, avoiding equipment failures caused by corrosion and flaking of the inner wall of the pipeline, ensuring normal production operation, and greatly extending the service life of the whole machine. Some models can have a built-in nitrogen tank to maximize the effective installation space for customers.

- The equipment supports continuous 24-hour uninterrupted supply of the required quality nitrogen, avoiding downtime caused by the depletion of gas cylinders. When expanding production capacity, there is no need to consider the cost of removing old equipment and replacing it with larger equipment. You only need to add the corresponding modules to meet the expansion requirements, which is convenient, fast, and cost-effective.

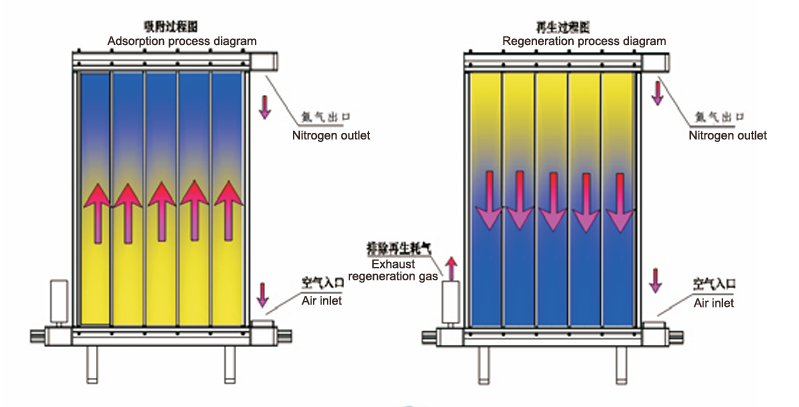

Working process

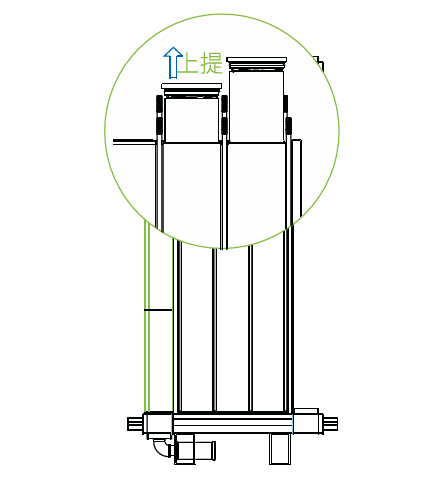

Weiteng modular nitrogen generator is composed of multiple high-strength aluminum alloy chambers. Each group of chambers is divided into two chambers, each chamber is filled with adsorbent to separate nitrogen and oxygen from compressed air. When one chamber is working (adsorbing), the other side relative to it is regenerated using the pressure swing adsorption method. During operation, compressed air diffuses evenly from the bottom of the adsorption chamber upwards, and the oxygen in the air is adsorbed by the adsorbent to achieve nitrogen-oxygen separation to obtain nitrogen. During regeneration, a portion of high-purity nitrogen expands from the working pressure to atmospheric pressure, passes through the oxygen-saturated adsorbent, and takes away the oxygen it has adsorbed, allowing the adsorbent to regenerate.

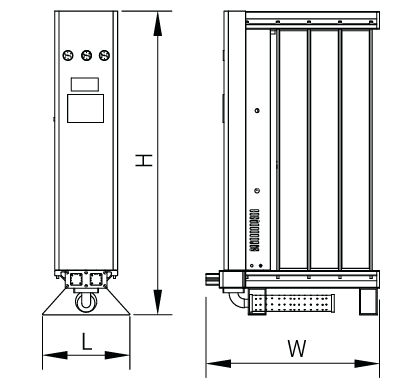

| Appearance structure advantages Weiteng modular nitrogen generator adopts an aluminum alloy chamber modular structure, which breaks through the traditional dual-tower appearance design. The equipment has a beautiful and generous appearance, and its volume is only about half of that of the traditional dual-tower nitrogen generator. The modular structure allows greater flexibility, it can save machine room space, and allows individual nitrogen generators to be placed in the workshop for high-purity nitrogen supply while keeping the factory clean. |

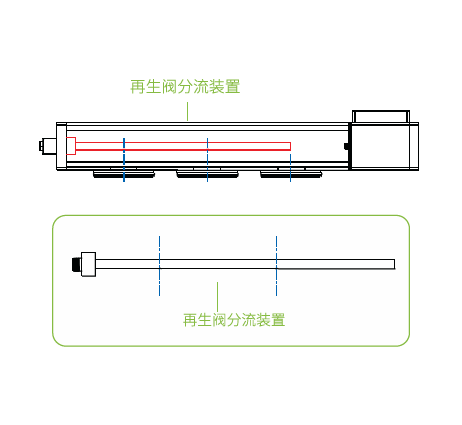

| Overall layout advantages The multi-pipe design of the adsorption chamber makes the body more compact and reasonable; the scientific fluid distribution design allows the gas to pass through the adsorption chamber at high speed and evenly, avoiding the tunnel effect of the adsorbent, and solves the problem of uneven airflow distribution in the original dual-tower adsorption tower, resulting in low adsorption efficiency and fast adsorbent pulverization rate. The adsorbent can fully separate nitrogen and oxygen in the air; the unique oxygen and corrosion protection treatment avoids secondary pollution to the gas caused by rusting of carbon steel pipes, making the structural parts more durable, the nitrogen cleaner, and the purity more stable. |

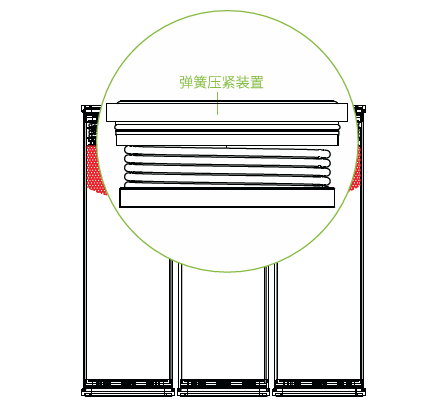

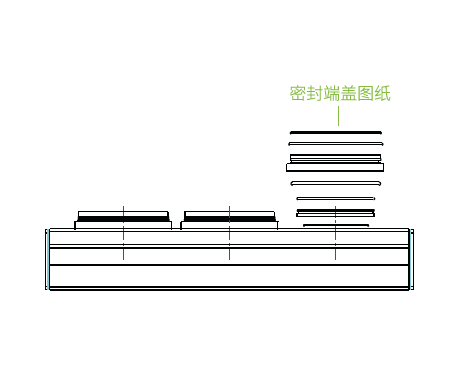

| Core efficiency advantages The adsorption chamber is composed of adsorption tubes, adsorbents, diffusion mesh plates, sealing materials, spring compression devices, and connecting components. The blizzard filling technology, combined with a unique spring compression device, makes the adsorbent filling tighter, eliminates the gap between the adsorbent and the end cover, not only prolongs the service life of the adsorbent, but also maximizes the adsorption efficiency, ensuring more stable nitrogen purity. |

| Stable performance advantages Each module has a separate diffuser to ensure uniform distribution of airflow, allowing each adsorbent to exert maximum adsorption energy; the new sealing end cover is composed of an outer dark cover and an inner dark cover, and uses a double end cover with five seals for all-round sealing protection, effectively preventing air leakage and improving nitrogen quality and enhancing service life. |

| Easy maintenance advantages A second layer of core module device is designed and installed in the adsorption chamber. The core module body adopts a high-temperature and corrosion-resistant plastic shell. The core module is filled with adsorbent. When replacing the adsorbent, only the core module needs to be taken out, which can realize rapid on-site replacement of the adsorbent and other problems, effectively solving the defects of dual-tower adsorption nitrogen generators such as large workload, long time, and loose filling when replacing the adsorbent. |

Advantages of modular nitrogen generator

- Average shunt technology, make full use of each adsorbent;

- Small size, suitable for various applications;

- No pressure vessel inspection is required, saving users money and time;

- The adsorption tower chamber is made of aluminum alloy, which is especially suitable for the food and pharmaceutical industries;

- Core module replacement technology, easy maintenance;

- The adsorption tower adopts a straight tube design, blizzard filling technology, and spring compression device to avoid the tunnel effect of the adsorbent.

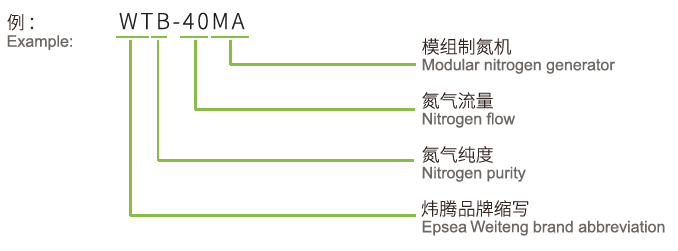

Nitrogen generator equipment model description

| Code Code | Nitrogen Purity Nitrogen purity |

| B | 98% |

| D | 99% |

| W | 99.5% |

| P | 99.9% |

| G | 99.99% |

| V | 99.999% |

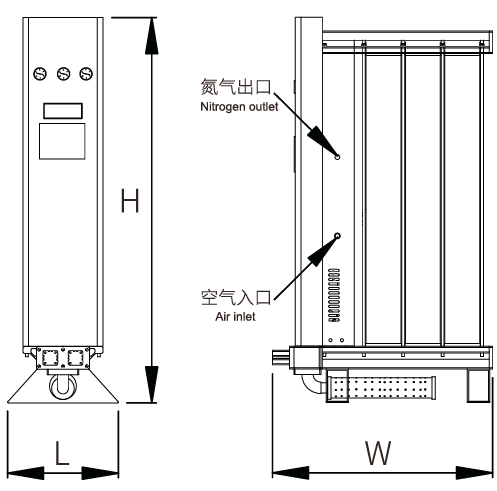

PSA modular nitrogen generator dimension chart

Modular Nitrogen Generator Parameters for Different Models

Purity 98% Series

| Model Specifications Model | Gas Production Flow rate (Nm/h) | Air Demand Demand capacity of air (Nm3/min) | Adsorption Pressure Adsorption pressure (Mpa) | Air Inlet Air inlet | Nitrogen Outlet Nitrogen outlet | Equipment Weight Weight (kg) | Equipment Dimensions (mm) Dimensions |

| L*W*H | |||||||

| WTB-10MZ | 10 | 0.3 | 0.7 | G1/2 | G1/2 | 100 | 500*600*1750 |

| WTB-20MZ | 20 | 0.5 | 0.7 | G1/2 | G1/2 | 160 | 500*780*1750 |

| WTB-30MZ | 30 | 0.85 | 0.7 | G1/2 | G1/2 | 220 | 500*960*1750 |

| WTB-40MZ | 40 | 1.2 | 0.7 | G1/2 | G1/2 | 280 | 500*1140*1750 |

| WTB-50MZ | 50 | 1.5 | 0.7 | G3/4 | G3/4 | 340 | 500*1320*1750 |

| WTB-60MZ | 60 | 1.85 | 0.7 | G3/4 | G3/4 | 400 | 500*1480*1750 |

| WTB-70MZ | 70 | 2 | 0.7 | G3/4 | G3/4 | 460 | 500*1660*1750 |

| WTB-80MZ | 80 | 2.5 | 0.7 | G3/4 | G3/4 | 520 | 500*1840*1750 |

| WTB-100MZ | 100 | 3 | 0.7 | G1 | G1 | 800 | 830*1320*1750 |

| WTB-120MZ | 120 | 3.8 | 0.7 | G1 | G1 | 1000 | 830*1480*1750 |

| WTB-140MZ | 140 | 4.5 | 0.7 | G1 | G1 | 1200 | 830*1660*1750 |

| WTB-160MZ | 160 | 5 | 0.7 | G1 | G1 | 1350 | 830*1840*1750 |

Note: 1. When the front end is equipped with a refrigerated dryer, the air compressor flow is increased by 10%, and the nitrogen dew point is below -30°C;

2. When the front end is equipped with a refrigerated dryer + adsorption dryer, the air compressor flow is increased by 20%, and the nitrogen dew point is below -40°C;

3. When the front end is equipped with a refrigerated dryer + adsorption dryer, enlarge 2 models, and the nitrogen dew point is below -50~-60°℃ under the corresponding flow of the air compressor.

Purity 99% Series

| Model Specifications Model | Gas Production Flow rate (Nm/h) | Air Demand Demand capacity of air (Nm3/min) | Adsorption Pressure Adsorption pressure (Mpa) | Air Inlet Air inlet | Nitrogen Outlet Nitrogen outlet | Equipment Weight Weight (kg) | Equipment Dimensions (mm) Dimensions |

| L*W*H | |||||||

| WTD-5MZ | 5 | 0.3 | 0.7 | G1/2 | G1/2 | 100 | 500*600*1750 |

| WTD-15MZ | 15 | 0.5 | 0.7 | G1/2 | G1/2 | 160 | 500*780*1750 |

| WTD-25MZ | 25 | 0.85 | 0.7 | G1/2 | G1/2 | 220 | 500*960*1750 |

| WTD-35MZ | 35 | 1.2 | 0.7 | G1/2 | G1/2 | 280 | 500*1140*1750 |

| WTD-45MZ | 45 | 1.5 | 0.7 | G3/4 | G3/4 | 340 | 500*1320*1750 |

| WTD-55MZ | 55 | 1.85 | 0.7 | G3/4 | G3/4 | 400 | 500*1480*1750 |

| WTD-60MZ | 60 | 2 | 0.7 | G3/4 | G3/4 | 460 | 500*1660*1750 |

| WTD-70MZ | 70 | 2.5 | 0.7 | G3/4 | G3/4 | 520 | 500*1840*1750 |

| WTD-90MZ | 90 | 3 | 0.7 | G1 | G1 | 800 | 830*1320*1750 |

| WTD-110MZ | 110 | 3.8 | 0.7 | G1 | G1 | 1000 | 830*1480*1750 |

| WTD-130MZ | 130 | 4.5 | 0.7 | G1 | G1 | 1200 | 830*1660*1750 |

| WTD-150MZ | 150 | 5.5 | 0.7 | G1 | G1 | 1350 | 830*1840*1750 |

Note: 1. When the front end is equipped with a refrigerated dryer, the air compressor flow is increased by 10%, and the nitrogen dew point is below -30°C;

2. When the front end is equipped with a refrigerated dryer + adsorption dryer, the air compressor flow is increased by 20%, and the nitrogen dew point is below -40°C;

3. When the front end is equipped with a refrigerated dryer + adsorption dryer, enlarge 2 models, and the nitrogen dew point is below -50~-60°℃ under the corresponding flow of the air compressor.

Purity 99.5% Series

| Model Specifications Model | Gas Production Flow rate (Nm/h) | Air Demand Demand capacity of air (Nm3/min) | Adsorption Pressure Adsorption pressure (Mpa) | Air Inlet Air inlet | Nitrogen Outlet Nitrogen outlet | Equipment Weight Weight (kg) | Equipment Dimensions (mm) Dimensions |

| L*W*H | |||||||

| WTW-5MZ | 5 | 0.3 | 0.7 | G1/2 | G1/2 | 100 | 500*600*1750 |

| WTW-15MZ | 15 | 0.5 | 0.7 | G1/2 | G1/2 | 160 | 500*780*1750 |

| WTW-20MZ | 20 | 0.85 | 0.7 | G1/2 | G1/2 | 220 | 500*960*1750 |

| WTW-25MZ | 25 | 1.2 | 0.7 | G1/2 | G1/2 | 280 | 500*1140*1750 |

| WTW-35MZ | 35 | 1.5 | 0.7 | G3/4 | G3/4 | 340 | 500*1320*1750 |

| WTW-45MZ | 45 | 1.85 | 0.7 | G3/4 | G3/4 | 400 | 500*1480*1750 |

| WTW-50MZ | 50 | 2 | 0.7 | G3/4 | G3/4 | 460 | 500*1660*1750 |

| WTW-60MZ | 60 | 2.5 | 0.7 | G3/4 | G3/4 | 520 | 500*1840*1750 |

| WTW-70MZ | 70 | 3 | 0.7 | G1 | G1 | 800 | 830*1320*1750 |

| WTW-90MZ | 90 | 3.8 | 0.7 | G1 | G1 | 1000 | 830*1480*1750 |

| WTW-100MZ | 100 | 4.5 | 0.7 | G1 | G1 | 1200 | 830*1660*1750 |

| WTW-120MZ | 120 | 5.2 | 0.7 | G1 | G1 | 1350 | 830*1840*1750 |

Note: 1. When the front end is equipped with a refrigerated dryer, the air compressor flow is increased by 10%, and the nitrogen dew point is below -30°C;

2. When the front end is equipped with a refrigerated dryer + adsorption dryer, the air compressor flow is increased by 20%, and the nitrogen dew point is below -40°C;

3. When the front end is equipped with a refrigerated dryer + adsorption dryer, enlarge 2 models, and the nitrogen dew point is below -50~-60°C under the corresponding flow of the air compressor.

Purity 99.9% Series

| Model Specifications Model | Gas Production Flow rate (Nm/h) | Air Demand Demand capacity of air (Nm3/min) | Adsorption Pressure Adsorption pressure (Mpa) | Air Inlet Air inlet | Nitrogen Outlet Nitrogen outlet | Equipment Weight Weight (kg) | Dimensions(mm) |

| L*W*H | |||||||

| WTP-5MZ | 5 | 0.3 | 0.7 | G1/2 | G1/2 | 100 | 500*600*1750 |

| WTP-10MZ | 10 | 0.5 | 0.7 | G1/2 | G1/2 | 160 | 500*780*1750 |

| WTP-15MZ | 15 | 0.85 | 0.7 | G1/2 | G1/2 | 220 | 500*960*1750 |

| WTP-20MZ | 20 | 1.2 | 0.7 | G1/2 | G1/2 | 280 | 500*1140*1750 |

| WTP-25MZ | 25 | 1.5 | 0.7 | G3/4 | G3/4 | 340 | 500*1320*1750 |

| WTP-30MZ | 30 | 1.85 | 0.7 | G3/4 | G3/4 | 400 | 500*1480*1750 |

| WTP-35MZ | 35 | 2 | 0.7 | G3/4 | G3/4 | 460 | 500*1660*1750 |

| WTP-40MZ | 40 | 2.5 | 0.7 | G3/4 | G3/4 | 520 | 500*1840*1750 |

| WTP-50MZ | 50 | 3 | 0.7 | G1 | G1 | 800 | 830*1320*1750 |

| WTP-60MZ | 60 | 3.8 | 0.7 | G1 | G1 | 1000 | 830*1480*1750 |

| WTP-70MZ | 70 | 4.5 | 0.7 | G1 | G1 | 1200 | 830*1660*1750 |

| WTP-80MZ | 80 | 5.2 | 0.7 | G1 | G1 | 1350 | 830*1840*1750 |

Note: 1. When the front end is equipped with a refrigerated dryer, the air compressor flow is increased by 10%, and the nitrogen dew point is below -30°C;

2. When the front end is equipped with a refrigerated dryer + adsorption dryer, the air compressor flow is increased by 20%, and the nitrogen dew point is below -40°C;

3. When the front end is equipped with a refrigerated dryer + adsorption dryer, enlarge 2 models, and the nitrogen dew point is below -50~-60°C under the corresponding flow of the air compressor.

99.99% purity series

| Model | Flow rate (Nm/h) | Demand capacity of air (Nm3/min) | Adsorption pressure (Mpa) | Air inlet | Nitrogen outlet | Weight (kg) | Dimensions(mm) |

| L*W*H | |||||||

| WTG-2MZ | 2 | 0.3 | 0.7 | G1/2 | G1/2 | 100 | 500*600*1750 |

| WTG-5MZ | 5 | 0.5 | 0.7 | G1/2 | G1/2 | 160 | 500*780*1750 |

| WTG-10MZ | 10 | 1.2 | 0.7 | G1/2 | G1/2 | 280 | 500*1140*1750 |

| WTG-15MZ | 15 | 1.5 | 0.7 | G3/4 | G3/4 | 340 | 500*1320*1750 |

| WTG-20MZ | 20 | 2 | 0.7 | G3/4 | G3/4 | 460 | 500*1660*1750 |

| WTG-25MZ | 25 | 2.5 | 0.7 | G3/4 | G3/4 | 520 | 500*1840*1750 |

| WTG-30MZ | 30 | 3 | 0.7 | G1 | G1 | 800 | 830*1320*1750 |

| WTG-35MZ | 35 | 3.5 | 0.7 | G1 | G1 | 1000 | 830*1480*1750 |

| WTG-40MZ | 40 | 4 | 0.7 | G1 | G1 | 1200 | 830*1660*1750 |

| WTG-50MZ | 50 | 4.5 | 0.7 | G1 | G1 | 1350 | 830*1840*1750 |

Note: 1. When the front end is equipped with a refrigerated dryer, the air compressor flow is increased by 10%, and the nitrogen dew point is below -30°C;

2、The front configuration includes a refrigerated dryer and a suction dryer, with a 20% increase in air compressor flow and a nitrogen dew point below -40 ° C;

3. When the front end is equipped with a refrigerated dryer + adsorption dryer, enlarge 2 models, and the nitrogen dew point is below -50~-60°℃ under the corresponding flow of the air compressor.

Purity 99.999% series

| Model | Flow rate (Nm/h) | Demand capacity of air (Nm3/min) | Adsorption pressure (Mpa) | Air inlet | Nitrogen outlet | Weight (kg) | Dimensions(mm) |

| L*W*H | |||||||

| WTV-2MZ | 2 | 0.3 | 0.7 | G1/2 | G1/2 | 100 | 500*600*1750 |

| WTV-5MZ | 5 | 1 | 0.7 | G1/2 | G1/2 | 220 | 500*960*1750 |

| WTV-10MZ | 10 | 1.2 | 0.7 | G1/2 | G1/2 | 280 | 500*1140*1750 |

| WTV-15MZ | 15 | 1.85 | 0.7 | G3/4 | G3/4 | 400 | 500*1480*1750 |

| WTV-20MZ | 20 | 2.5 | 0.7 | G3/4 | G3/4 | 520 | 500*1840*1750 |

| WTV-25MZ | 25 | 3 | 0.7 | G1 | G1 | 800 | 830*1320*1750 |

| WTV-30MZ | 30 | 3.5 | 0.7 | G1 | G1 | 1000 | 830*1480*1750 |

| WTV-35MZ | 35 | 4 | 0.7 | G1 | G1 | 1200 | 830*1660*1750 |

| WTV-40MZ | 40 | 4.5 | 0.7 | G1 | G1 | 1350 | 830*1840*1750 |

Note: 1. When the front end is equipped with a refrigerated dryer, the air compressor flow is increased by 10%, and the nitrogen dew point is below -30°C;

2. When the front end is equipped with a refrigerated dryer + adsorption dryer, the air compressor flow is increased by 20%, and the nitrogen dew point is below -40°C;

3. When the front end is equipped with a refrigerated dryer + adsorption dryer, enlarge 2 models, and the nitrogen dew point is below -50~-60°C under the corresponding flow of the air compressor.

4、The nitrogen purity of 99.999% is the displayed value, which is slightly different from the true purity of 99.999%.

Note: Our company has the right to make design changes to the product. If there are any parameter changes, we will not notify you separately.

Previous page:

Next:

Previous page:

Leave a message

Get Price and Free Sample Now!

Xiaobian Village, Yu Neng Industrial Park, Houjie Town, Dongguan City, Guangdong Province

Request a quote

Get Price and Free Sample Now!

© Copyright XINBAO AIR COMPRESSOR All rights reserved

Power by:www.300.cn | SEO | Privacy Policy