Product Search

Quickly find the products you need

Double Tower Pressure Swing Adsorption Nitrogen Generator

Parameters of Different Models of Nitrogen Generators

Nitrogen Purity: 98~99.999%

Maximum Inlet Air Temperature: ≤40°C

Minimum Inlet Air Temperature: 5°C

Minimum Inlet Air Pressure: 0.6MPa

Maximum Ambient Temperature: ≤45°C

Power Supply Requirements: 220V 50Hz/110V DC24V

Noise: <70dB

Nitrogen Dew Point: ≤-40℃

Control Method

Standard: PLC Programmable

Advanced: Human-Machine Touch Interface

Category:

Keywords:

Product Description

Core Components

Equipped with the best domestic pneumatic angle seat valve, with an effective valve action exceeding 3.5 million cycles and a lifespan of over 8 years, ensuring stable operation of the nitrogen generator. |

Cooperating with high-quality domestic and international manufacturers to allocate the most economical and energy-saving molecular sieves based on customer usage. |

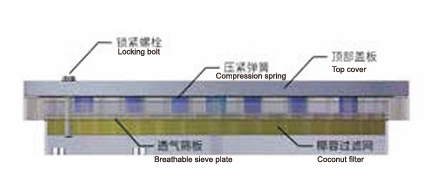

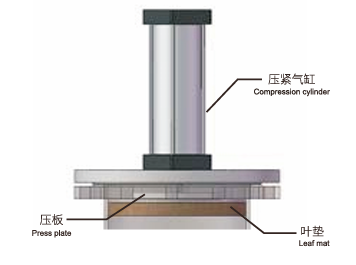

Using imported coconut fiber pads with high density and strong toughness to ensure effective particle filtration, preventing powdering and sieve leakage. |

Using Siemens PLC control to prevent garbled codes and program anomalies, ensuring normal equipment operation. |

Using original Taiwan Airtac control components to ensure normal valve operation and extend service life. |

Selecting top domestic gas analyzers with high precision, actual measurement deviation <0.001, long lifespan exceeding 5 years. |

Product Features

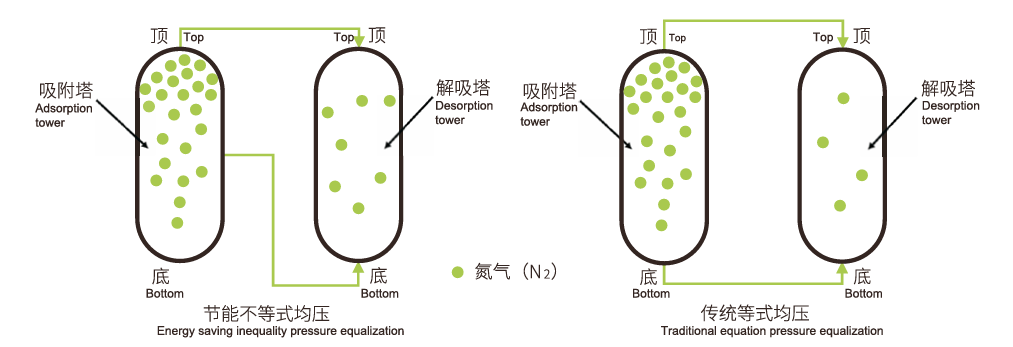

- Advanced energy-saving unequal pressure equalization structure improves adsorbent utilization and directly reduces compressed air consumption.

- Advanced internal structure ensures uniform airflow distribution, reduces impact on adsorbent, and extends adsorbent service life.

- Cooperating with well-known domestic and international carbon molecular sieve manufacturers to select the most energy-efficient and effective ratio according to actual working conditions.

- Reliable air source treatment accessories ensure stable equipment operation and service life.

- Using snowstorm filling method to make adsorbent filling more uniform and compact, minimizing friction coefficient and improving long-term reliability of the whole machine.

- Using Siemens PLC programmable controller for automatic control, one-key start without special operation, and reserved connection for remote devices such as computers and mobile phones for real-time monitoring.

- Using well-known domestic stainless steel pneumatic angle seat valves featuring fast opening and closing speed, low energy consumption, good sealing performance, easy installation and maintenance, and long service life.

- Using a special spring pressing device that automatically compensates when the volume of carbon molecular sieve in the adsorption tower decreases, preventing powdering and extending service life.

- Equipped with automatic/manual purge device for unqualified nitrogen (optional).

- Selecting famous domestic and international brand components to ensure stable equipment operation and nitrogen quality.

Gas Diffusion Device

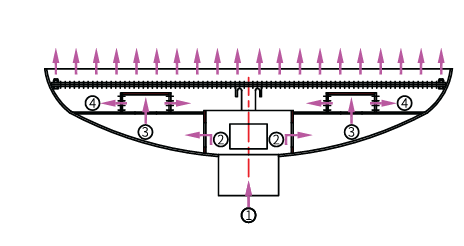

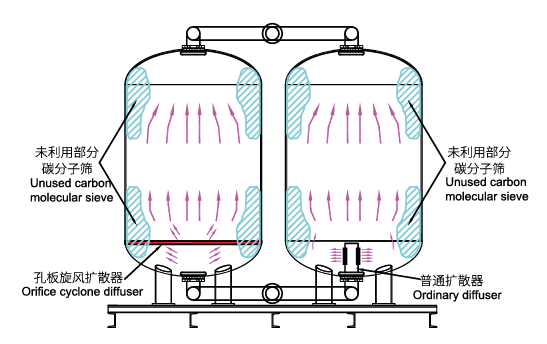

Weiteng's unique airflow diffuser forcibly splits compressed air into surface diffusion, avoiding airflow dead zones and channeling effects, improving adsorbent utilization and nitrogen production rate. |

Conventional two types of airflow diffusers easily create airflow dead zones, causing incomplete adsorbent utilization and leading to adsorbent powdering and channeling reactions, directly affecting nitrogen quality and adsorbent life. |

Self-operated spring pressing device

Cylinder-type pressing device

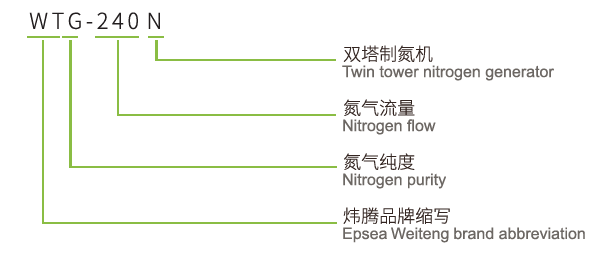

Nitrogen Generator Equipment Model Description

| Code Code |

Nitrogen Purity Nitrogen purity |

| B | 98% |

| D | 99% |

| W | 99.5% |

| P | 99.9% |

| G | 99.99% |

| V | 99.999% |

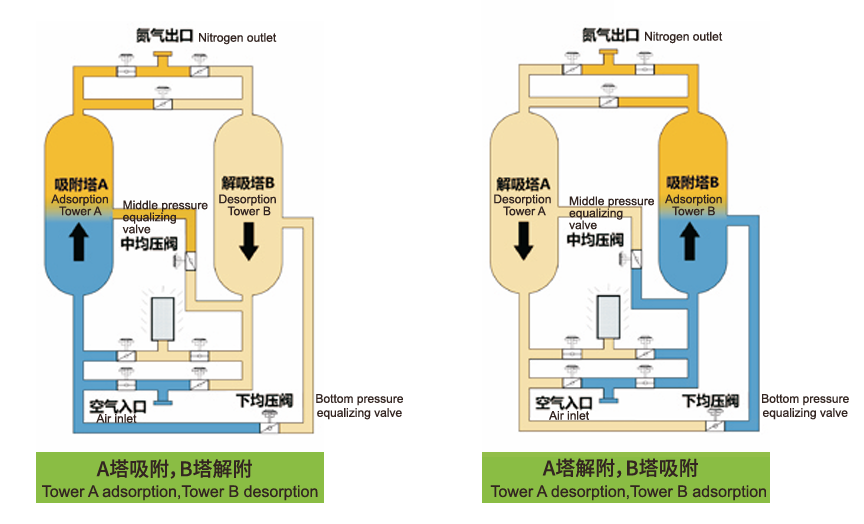

Working Process

Clean compressed air enters the adsorption tower filled with carbon molecular sieve from the bottom. After diffusion by a specially structured equalizing diffuser, the airflow evenly enters the adsorption tower for oxygen-nitrogen adsorption separation. High-purity nitrogen is produced from the top of the adsorption tower and sent to the nitrogen process tank for storage; a small amount of product nitrogen enters the regeneration tower to blow off the adsorbed oxygen on the carbon molecular sieve for regeneration. Two adsorption towers alternate cyclic operation, continuously feeding raw air and continuously producing nitrogen.

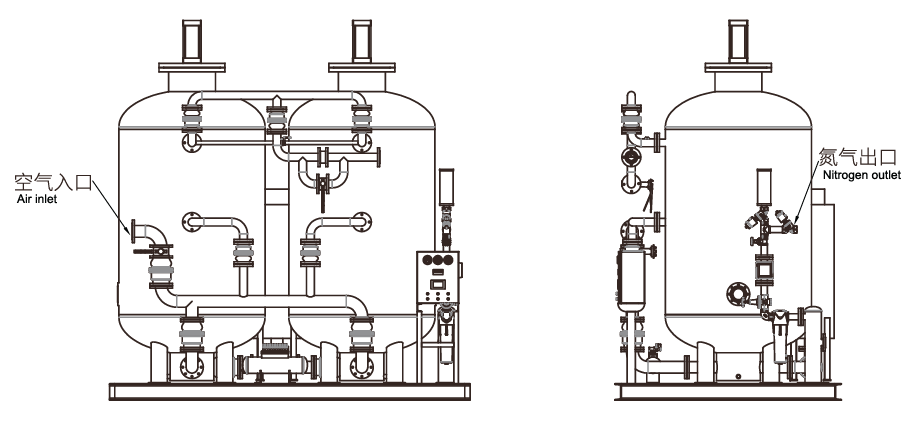

PSA Double Tower Nitrogen Generator Dimension Chart

Parameters of Different Models of Double Tower Nitrogen Generators

98% Purity Series

| Model Specification Model |

Gas Production Flow rate (Nm3/h) |

Air Demand Demand capacity of air (Nm3/min) |

Adsorption Pressure Adsorption pressure (Mpa) |

Air Inlet Air inlet |

Nitrogen Outlet Nitrogen outlet |

Equipment Dimensions (mm) Dimensions |

| L*W*H | ||||||

| WTB-60N | 60 | 2.2 | 0.7 | G1 | G1 | 1500*1500*2350 |

| WTB-120N | 120 | 4.4 | 0.7 | G1*1/4 | G1 | 1850*1650*2450 |

| WTB-150N | 150 | 5.5 | 0.7 | G1*1/4 | G1*1/2 | 2000*1650*2450 |

| WTB-180N | 180 | 6.6 | 0.7 | G1*1/2 | G1*1/2 | 2200*1850*2500 |

| WTB-230N | 230 | 8.5 | 0.7 | G1*1/2 | G1*1/2 | 2200*1900*2890 |

| WTB-300N | 300 | 11.0 | 0.7 | G1*1/2 | G1*1/2 | 2350*2050*3100 |

| WTB-350N | 350 | 13 | 0.7 | G2 | G1*1/2 | 2350*2050*3250 |

| WTB-400N | 400 | 14.5 | 0.7 | G2 | G1*1/2 | 2400*1300*3250 |

| WTB-450N | 450 | 16.5 | 0.7 | G2 | G2 | 2500*1400*3200 |

| WTB-550N | 550 | 20 | 0.7 | G2 | G2 | 2700*1500*3200 |

| WTB-600N | 600 | 22 | 0.7 | G2*1/2 | G2 | 2700*1500*3250 |

| WTB-650N | 650 | 24 | 0.7 | G2*1/2 | G2 | 2800*1500*3250 |

| WTB-750N | 750 | 27.5 | 0.7 | G2*1/2 | G2*1/2 | 3000*1600*3300 |

| WTB-850N | 850 | 31.5 | 0.7 | G2*1/2 | G2*1/2 | 3100*2000*3540 |

| WTB-900N | 900 | 33 | 0.7 | G3 | G2*1/2 | 3300*2100*3600 |

| WTB-1000N | 1000 | 37 | 0.7 | G3 | G2*1/2 | 3500*2200*3600 |

| WTB-1200N | 1200 | 44 | 0.7 | G3 | G3 | 3800*2500*3600 |

| WTB-1400N | 1400 | 52 | 0.7 | G4 | G3 | 4000*2500*3600 |

| WTB-1500N | 1500 | 55 | 0.7 | G4 | G3 | 4200*2600*3600 |

| WTB-1800N | 1800 | 66 | 0.7 | G4 | G3 | 4500*2800*3600 |

Purity 99% Series

| Model Specifications Model |

Gas Production Flow rate (Nm/h) |

Air Demand Demand capacity of air (Nm3/min) |

Adsorption Pressure Adsorption Pressure (Mpa) |

Air Inlet Air inlet |

Nitrogen Outlet Nitrogen outlet |

Equipment Dimensions (mm) Dimensions |

| L*W*H | ||||||

| WTD-50N | 50 | 2 | 0.7 | G1 | G1 | 1500*1500*2350 |

| WTD-90N | 90 | 3.5 | 0.7 | G1*1/4 | G1 | 1850*1650*2450 |

| WTD-110N | 110 | 4.2 | 0.7 | G1*1/4 | G1*1/2 | 2000*1650*2450 |

| WTD-140N | 140 | 5.5 | 0.7 | G1*1/2 | G1*1/2 | 2200*1850*2500 |

| WTD-170N | 170 | 6.5 | 0.7 | G1*1/2 | G1*1/2 | 2200*1900*2890 |

| WTD-220N | 220 | 8.5 | 0.7 | G1*1/2 | G1*1/2 | 2350*2050*3100 |

| WTD-280N | 280 | 10.8 | 0.7 | G2 | G1*1/2 | 2350*2050*3250 |

| WTD-330N | 330 | 12.7 | 0.7 | G2 | G1*1/2 | 2400*1300*3250 |

| WTD-420N | 420 | 16 | 0.7 | G2 | G2 | 2500*1400*3200 |

| WTD-500N | 500 | 19 | 0.7 | G2 | G2 | 2700*1500*3200 |

| WTD-550N | 550 | 21 | 0.7 | G2*1/2 | G2 | 2700*1500*3250 |

| WTD-600N | 600 | 23 | 0.7 | G2*1/2 | G2 | 2800*1500*3250 |

| WTD-700N | 700 | 27 | 0.7 | G2*1/2 | G2*1/2 | 3000*1600*3300 |

| WTD-750N | 750 | 29 | 0.7 | G2*1/2 | G2*1/2 | 3100*2000*3540 |

| WTD-800N | 800 | 31 | 0.7 | G3 | G2*1/2 | 3300*2100*3600 |

| WTD-950N | 950 | 36.5 | 0.7 | G3 | G2*1/2 | 3500*2200*3600 |

| WTD-1100N | 1100 | 43 | 0.7 | G3 | G3 | 3800*2500*3600 |

| WTD-1200N | 1200 | 46 | 0.7 | G4 | G3 | 4000*2500*3600 |

| WTD-1400N | 1400 | 54 | 0.7 | G4 | G3 | 4200*2600*3600 |

| WTD-1600N | 1600 | 61.5 | 0.7 | G4 | G3 | 4500*2800*3600 |

Note: (The following configurations are for general reference in selection. For specific performance indicators, please contact engineering personnel.) 1. When a refrigerated dryer is configured in the front section, increase the air compressor flow by 10%, nitrogen dew point below -30°C;

2. When a refrigerated dryer + adsorption dryer is configured in the front section, increase the air compressor flow by 20%, nitrogen dew point below -40°C;

3. When a refrigerated dryer + adsorption dryer is configured in the front section, increase by 2 model sizes, with the corresponding air compressor flow, nitrogen dew point below -50~-60°C.

Purity 99.5% Series

| Model Specifications Model |

Gas Production Flow rate (Nm3/h) |

Air Demand Demand capacity of air (Nm3/min) |

Adsorption Pressure Adsorption Pressure (Mpa) |

Air Inlet Air inlet |

Nitrogen Outlet Nitrogen outlet |

Equipment Dimensions (mm) Dimensions |

| L*W*H | ||||||

| WTW-40N | 40 | 1.8 | 0.7 | G1 | G1 | 1500*1500*2350 |

| WTW-70N | 70 | 3.1 | 0.7 | G1*1/4 | G1 | 1850*1650*2450 |

| WTW-100N | 100 | 4.4 | 0.7 | G1*1/4 | G1*1/2 | 2000*1650*2450 |

| WTW-120N | 120 | 5.2 | 0.7 | G1*1/2 | G1*1/2 | 2200*1850*2500 |

| WTW-140N | 140 | 6.0 | 0.7 | G1*1/2 | G1*1/2 | 2200*1900*2890 |

| WTW-200N | 200 | 8.6 | 0.7 | G1*1/2 | G1*1/2 | 2350*2050*3100 |

| WTW-250N | 250 | 11 | 0.7 | G2 | G1*1/2 | 2350*2050*3250 |

| WTW-300N | 300 | 13 | 0.7 | G2 | G1*1/2 | 2400*1300*3250 |

| WTW-350N | 350 | 15.2 | 0.7 | G2 | G2 | 2500*1400*3200 |

| WTW-450N | 450 | 19.5 | 0.7 | G2 | G2 | 2700*1500*3200 |

| WTW-500N | 500 | 22 | 0.7 | G2*1/2 | G2 | 2700*1500*3250 |

| WTW-550N | 550 | 24 | 0.7 | G2*1/2 | G2 | 2800*1500*3250 |

| WTW-600N | 600 | 26 | 0.7 | G2*1/2 | G2*1/2 | 3000*1600*3300 |

| WTW-650N | 650 | 28.3 | 0.7 | G2*1/2 | G2*1/2 | 3100*2000*3540 |

| WTW-700N | 700 | 31 | 0.7 | G3 | G2*1/2 | 3300*2100*3600 |

| WTW-800N | 800 | 35 | 0.7 | G3 | G2*1/2 | 3500*2200*3600 |

| WTW-1000N | 1000 | 43.5 | 0.7 | G3 | G3 | 3800*2500*3600 |

| WTW-1100N | 1100 | 48 | 0.7 | G4 | G3 | 4000*2500*3600 |

| WTW-1200N | 1200 | 52 | 0.7 | G4 | G3 | 4200*2600*3600 |

| WTW-1400N | 1400 | 61 | 0.7 | G4 | G3 | 4500*2800*3600 |

Purity 99.9% Series

| Model Specifications Model |

Gas Production Flow rate (Nm/h) |

Air Demand Demand capacity of air (Nm3/min) |

Adsorption Pressure Adsorption Pressure (Mpa) |

Air Inlet Air inlet |

Nitrogen Outlet Nitrogen outlet |

Equipment Dimensions (mm) Dimensions |

| L*W*H | ||||||

| WTP-30N | 30 | 1.9 | 0.7 | G1 | G1 | 1500*1500*2350 |

| WTP-50N | 50 | 3.1 | 0.7 | G1*1/4 | G1 | 1850*1650*2450 |

| WTP-70N | 70 | 4.2 | 0.7 | G1*1/4 | G1 | 2000*1650*2450 |

| WTP-90N | 90 | 5.5 | 0.7 | G1*1/2 | G1 | 2200*1850*2500 |

| WTP-110N | 110 | 6.6 | 0.7 | G1*1/2 | G1*1/2 | 2200*1900*2890 |

| WTP-130N | 130 | 7.8 | 0.7 | G1*1/2 | G1*1/2 | 2350*2050*3100 |

| WTP-150N | 150 | 9 | 0.7 | G2 | G1*1/2 | 2350*2050*3250 |

| WTP-200N | 200 | 12 | 0.7 | G2 | G1*1/2 | 2400*1300*3250 |

| WTP-250N | 250 | 15 | 0.7 | G2 | G1*1/2 | 2500*1400*3200 |

| WTP-300N | 300 | 18 | 0.7 | G2 | G1*1/2 | 2700*1500*3200 |

| WTP-350N | 350 | 21 | 0.7 | G2*1/2 | G2 | 2700*1500*3250 |

| WTP-370N | 370 | 22.2 | 0.7 | G2*1/2 | G2 | 2800*1500*3250 |

| WTP-400N | 400 | 24 | 0.7 | G2*1/2 | G2 | 3000*1600*3300 |

| WTP-450N | 450 | 27 | 0.7 | G2*1/2 | G2 | 3100*2000*3540 |

| WTP-500N | 500 | 30 | 0.7 | G3 | G2 | 3300*2100*3600 |

| WTP-600N | 600 | 36 | 0.7 | G3 | G2*1/2 | 3500*2200*3600 |

| WTP-700N | 700 | 42 | 0.7 | G3 | G2*1/2 | 3800*2500*3600 |

| WTP-750N | 750 | 45 | 0.7 | G4 | G2*1/2 | 4000*2500*3600 |

| WTP-800N | 800 | 48 | 0.7 | G4 | G2*1/2 | 4200*2600*3600 |

| WTP-1000N | 1000 | 60 | 0.7 | G4 | G2*1/2 | 4500*2800*3600 |

Note: (The following configurations are for general reference in selection. For specific performance indicators, please contact engineering personnel.) 1. When a refrigerated dryer is configured in the front section, increase the air compressor flow by 10%, nitrogen dew point below -30°C;

2. When a refrigerated dryer + adsorption dryer is configured in the front section, increase the air compressor flow by 20%, nitrogen dew point below -40°C; 3. When a refrigerated dryer + adsorption dryer is configured in the front section, increase by 2 model sizes, with the corresponding air compressor flow, nitrogen dew point below -50~-60°C.

Purity 99.99% Series

| Model Specifications Model |

Gas Production Flow rate (Nm3/h) |

Air Demand Demand capacity of air (Nm3/min) |

Adsorption Pressure Adsorption (Mpa) |

Air Inlet Air inlet |

Nitrogen Outlet Nitrogen outlet |

Equipment Dimensions (mm) Dimensions |

| L*W*H | ||||||

| WTG-20N | 20 | 1.8 | 0.7 | G1 | G1 | 1500*1500*2350 |

| WTG-30N | 30 | 2.7 | 0.7 | G1*1/4 | G1 | 1850*1650*2450 |

| WTG-40N | 40 | 3.6 | 0.7 | G1*1/4 | G1 | 2000*1650*2450 |

| WTG-50N | 50 | 4.5 | 0.7 | G1*1/2 | G1 | 2200*1850*2500 |

| WTG-60N | 60 | 5.3 | 0.7 | G1*1/2 | G1 | 2200*1900*2890 |

| WTG-80N | 80 | 7.0 | 0.7 | G1*1/2 | G1 | 2350*2050*3100 |

| WTG-100N | 100 | 8.8 | 0.7 | G2 | G1*1/2 | 2350*2050*3250 |

| WTG-120N | 120 | 10.6 | 0.7 | G2 | G1*1/2 | 2400*1300*3250 |

| WTG-150N | 150 | 13.5 | 0.7 | G2 | G1*1/2 | 2500*1400*3200 |

| WTG-180N | 180 | 16 | 0.7 | G2 | G1*1/2 | 2700*1500*3200 |

| WTG-200N | 200 | 17.8 | 0.7 | G2*1/2 | G1*1/2 | 2700*1500*3250 |

| WTG-220N | 220 | 19.5 | 0.7 | G2*1/2 | G1*1/2 | 2800*1500*3250 |

| WTG-250N | 250 | 22 | 0.7 | G2*1/2 | G1*1/2 | 3000*1600*3300 |

| WTG-300N | 300 | 27 | 0.7 | G2*1/2 | G2 | 3100*2000*3540 |

| WTG-350N | 350 | 31 | 0.7 | G3 | G2 | 3300*2100*3600 |

| WTG-400N | 400 | 35.5 | 0.7 | G3 | G2 | 3500*2200*3600 |

| WTG-450N | 450 | 40 | 0.7 | G3 | G2 | 3800*2500*3600 |

| WTG-500N | 500 | 44.5 | 0.7 | G4 | G2 | 4000*2500*3600 |

| WTG-550N | 550 | 48.5 | 0.7 | G4 | G2*1/2 | 4200*2600*3600 |

| WTG-600N | 600 | 53 | 0.7 | G4 | G2*1/2 | 4500*2800*3600 |

Purity 99.999% Series

| Model Specifications Model |

Gas Production Flow rate (Nm/h) |

Air demand Demand capacity of air (Nm3/min) |

Adsorption pressure Adsorption Pressure (Mpa) |

Air inlet Air inlet |

Nitrogen outlet Nitrogen outlet |

Equipment dimensions (mm) Dimensions |

| L*W*H | ||||||

| WTV-15N | 15 | 2.7 | 0.7 | G1 | G1 | 1500*1500*2350 |

| WTV-20N | 20 | 3.6 | 0.7 | G1*1/4 | G1 | 1850*1650*2450 |

| WTV-30N | 30 | 4.5 | 0.7 | G1*1/4 | G1 | 2000*1650*2450 |

| WTV-40N | 40 | 5.3 | 0.7 | G1*1/2 | G1 | 2200*1850*2500 |

| WTV-50N | 50 | 7.0 | 0.7 | G1*1/2 | G1 | 2200*1900*2890 |

| WTV-70N | 70 | 8.8 | 0.7 | G1*1/2 | G1 | 2350*2050*3100 |

| WTV-80N | 80 | 10.6 | 0.7 | G2 | G1 | 2350*2050*3250 |

| WTV-100N | 100 | 13.5 | 0.7 | G2 | G1 | 2400*1300*3250 |

| WTV-130N | 130 | 16 | 0.7 | G2*1/2 | G1*1/2 | 2500*1400*3250 |

| WTV-150N | 150 | 17.8 | 0.7 | G2*1/2 | G1*1/2 | 2700*1500*3250 |

| WTV-170N | 170 | 19.5 | 0.7 | G2*1/2 | G1*1/2 | 2700*1500*3250 |

| WTV-200N | 200 | 22 | 0.7 | G2*1/2 | G1*1/2G | 2800*1500*3250 |

Note: (The following configuration is for general reference selection. For specific performance indicators, please contact engineering personnel. The above is a one-step method with a displayed purity of 99.99996 and oxygen content of 10ppm ±5)

1. When a refrigerated dryer is configured in the front section, increase the air compressor flow by 10%, nitrogen dew point below -30°C;

2. When a refrigerated dryer + adsorption dryer are configured in the front section, increase the air compressor flow by 20%, nitrogen dew point below -40°C;

3. When a refrigerated dryer + adsorption dryer is configured in the front section, increase by 2 model sizes, with the corresponding air compressor flow, nitrogen dew point below -50~-60°C.

Previous page:

Previous page:

Next page:

Leave a message

Get Price and Free Sample Now!

Xiaobian Village, Yu Neng Industrial Park, Houjie Town, Dongguan City, Guangdong Province

Request a quote

Get Price and Free Sample Now!

© Copyright XINBAO AIR COMPRESSOR All rights reserved

Power by:www.300.cn | SEO | Privacy Policy